Cribbs Mill Creek Drainage Improvements - Phase 1

Forterra

Location:

City of Tuscaloosa

Tuscaloosa, AL

Schedule:

Project Start Date: 2018

Project Completion Date: 2019

Cost:

Total Project Cost: $4.6 million

Involved Companies

Precast Concrete Producer

Forterra Structural Products

400 Industrial Park Drive

Pelham, AL 35124

https://forterrabp.com/

Structural Engineer

MAK Engineering

351 Canyon Park Drive

Pelham, AL 35124

http://makegr.com/

General Contractor

IKAROS

3700 Commerce Drive

Tuscaloosa, AL 35401

Background

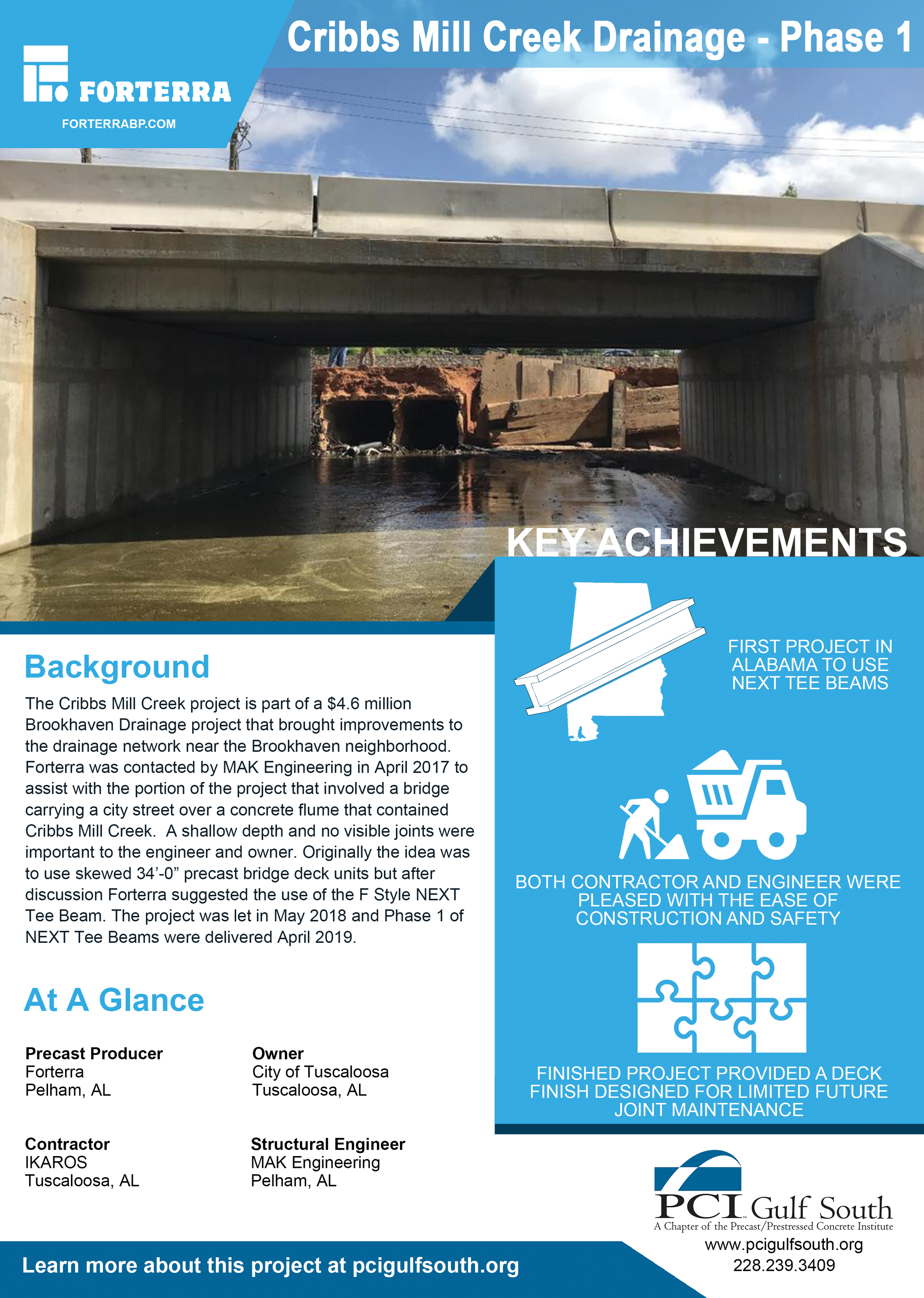

The Cribbs Mill Creek project is part of a $4.6 million Brookhaven Drainage project that brought improvements to the drainage network near the Brookhaven neighborhood. The improvements were implemented to help protect the local community from a 100-year flood event.

Forterra was contacted by MAK Engineering in April 2017 to assist with the portion of the project that involved a bridge carrying a city street over a concrete flume that contained Cribbs Mill Creek. A shallow depth and no visible joints were important to the engineer and owner. Originally, the idea was to use skewed 34’-0” precast bridge deck units but after discussion, Forterra suggested the use of the F Style NEXT Tee Beam.

The NEXT Tee beam was cast in widths up to 11’-0” wide which greatly reduced the number of pieces required (8 NEXT Tees) verses a standard precast bridge deck (24 Units).

The project was let in May 2018 and Phase 1 of NEXT Tee Beams were delivered April 2019.

Bridge Info

Length = 38’-3 ¾”

Width = 82’-0 ½”

15 Deg. Skew

3 ea. NEXT Tees @ 10’-9 ½” wide x 36’-3 ¾” long (Phase I)

5 ea. NEXT Tees @ 9’-10 ½” wide x 36’-3 ¾” long (Phase II)

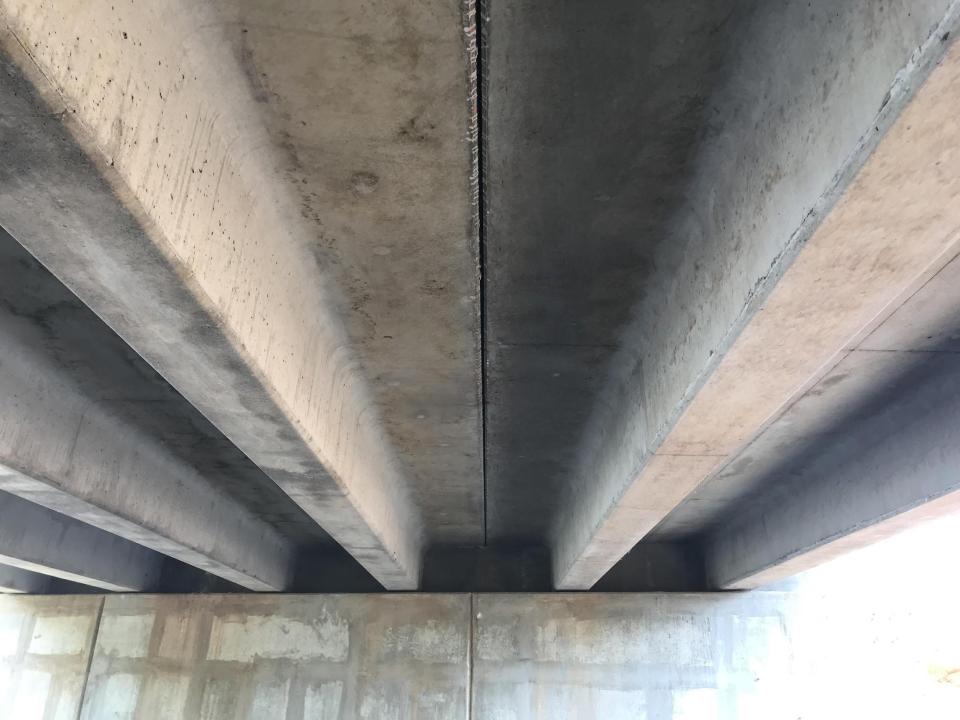

NEXT Tees were cast with a flat top. An 8” deck was cast on top of the Tees with a 2% slope for drainage.

The total cost for the NEXT Tee beams was comparable to 34’-0” precast deck units for this particular application.

Innovations/Accomplishments

This is the first project in the state of Alabama to use the NEXT Tee beams

Contractor and Engineer are both pleased with the ease of construction, safety and appearance..

Finished structure provides a clean line profile, as well as a solid deck finish, without joint lines and possible future joint maintenance.