Precast Enclosure Systems

Precast, as an enclosure system, provides a distinct advantage over other building materials. Precast walls act as both the structural support for a structure and the component that provides the building’s insulation. By choosing precast, designers and clients are choosing a product that lasts a life-time and provides the support and protection needed to keep residents safe.

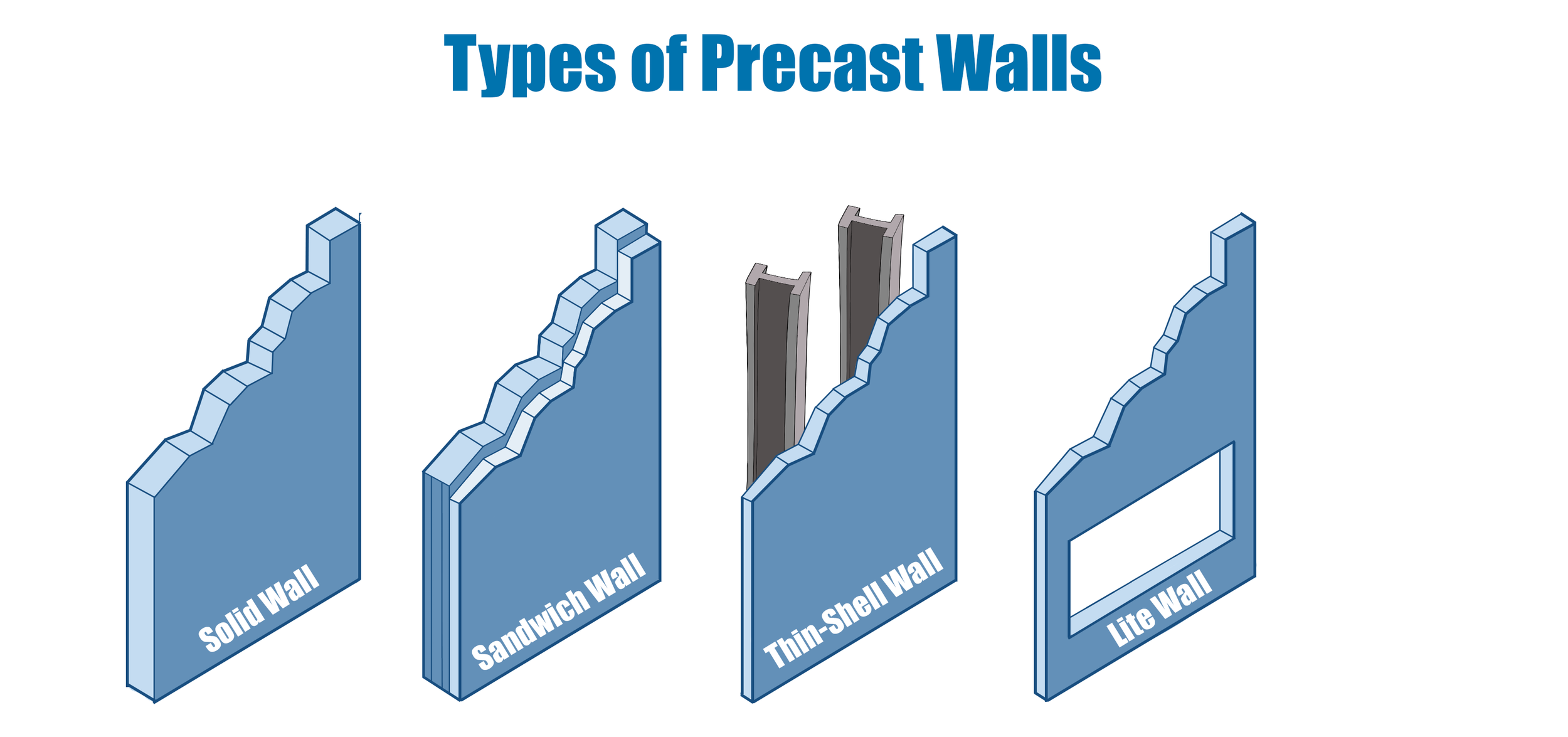

Types of Precast Walls

The versatility of precast walls ranges from providing architectural cladding for the exterior of a structure to a total precast system that provides insulation and structural support for the overall building. The following graphic depicts different types of precast walls.

Solid Walls

Solid walls are manufactured completely of concrete with insulation added to the interior finishing wall system. These types of walls can have any type of finish added to the back.

Sandwich Walls

Sandwich walls encompass the normal characteristics of a standard precast concrete wall with the added benefit of insulation which provides energy performance and moisture protection. More information about sandwich walls can be found in the State of the Art Sandwich Wall Panel technical document.

Thin-Shell and GFRC

Thin-shell wall panels are made from a thin outer-wythe of concrete and are connected to the backup structural system which usually consists of steel or concrete. Glass fiber-reinforced concrete (GFRC) is a type of thin-shell system which includes concrete that contains alkali-resistant glass fibers.

Lite Walls

Lite walls are used on precast structures and involve shear walls with a void that provides openness and a feeling of security.

Depending on the needs of a client, one or more of these types of walls can be used to create the enclosure of the structure.

PCI’s Designer’s Notebook: Envelope Tolerances for Architectural Precast discusses the tolerances and clearances required for joining different building materials.

PCI also offers a collection of technical documents regarding Building Enclosure Design here for professionals looking for more guidance in designing building enclosures with precast.

Benefits

Like other precast components, precast walls provide valuable benefits for a building’s enclosure. Some of the benefits include:

Moisture Resistance: Precast wall systems are a barrier or face-sealed systems. They are superior to rainscreen systems because they do not require a space where water can collect and cause further issues. There are several supporting technical documents on the Building Enclosure Design web page under Air and Moisture Management.

Thermal Mass: Precast concrete buildings save energy in various types of climates due to their ability to absorb and store heat and react very slowly to changes in outside temperature. This is further discussed in PCI’s Thermal Mass technical document.

Quick Erection: Precast building enclosures can be erected in a few days or weeks which greatly reduces the overall project construction schedule.

Eliminates Threats: The speed of installation eliminates the need for fireproofing, termite treatments, and additional insulation.

Versatility: Precast walls can be designed to match a specific color or texture and help buildings blend into their surroundings in urban environments or match existing nearby structures.

When used as a building enclosure, precast/prestressed concrete provides substantial benefits to both the owners and occupants of the structure. The versatility of concrete allows for designs of all sizes, shapes, and colors which meets the unique characteristics of each project.