BLOG

Discover everything there is to know about precast concrete with our in-depth articles, ranging from its unmatched sustainability to its aesthetic versatility. Our blog features in-depth articles demonstrating how precast concrete can revolutionize your projects, combining cutting-edge design with durable performance and environmentally sustainable solutions, whether you're an architect, engineer, or contractor.

Come explore the various ways precast influences the built environment with us!

The architecture of the Gulf South is a dynamic fusion of styles with a long, rich history of various influences and environmental considerations. Because of the region's architectural diversity, robust and adaptable building materials are required to keep the buildings standing for decades. The perfect answer for meeting these various architectural needs is precast concrete, which allows architects and builders to alter designs to suit the unique structural, aesthetic, and sustainability requirements of the Gulf South.

The Gulf South is renowned for its breathtaking scenery, but nature also poses a persistent threat to the region. This area experiences frequent extreme weather, such as hurricanes, flooding, and strong winds.

Safeguarding these communities requires more than just putting a plan in place; it also calls for strengthening existing structures.

Disasters are an awful reality in the Gulf South, where hurricanes, floods, and other natural disasters constantly threaten infrastructure. In the face of these difficulties, the use of durable building materials, such as precast concrete, becomes essential.

Imagine a busy school campus that is ablaze with student laughter, the sound of learning, and the promise of a day when innovation meets education. One material stands out for its adaptability, durability, and visual appeal as architects and educators work together to design the schools of the future: precast concrete.

Efficiency is critical in the fast-paced field of school construction. With its unmatched durability, cost-effectiveness, and expedited timescales, precast concrete has become a game-changer. This blog examines how precast concrete technologies, which shorten construction times and improve sustainability, are transforming school building projects. Learn about the numerous advantages of using precast concrete in school infrastructure for a future that is more durable and efficient.

Picture this: a classroom buzzing with energy, where walls don't just hold up the roof but inspire minds, and floors aren't just surfaces but pathways to discovery. Prepare to be transported into a world where imagination meets innovation, where precast concrete isn't just a material but a storyteller in the narrative of education.

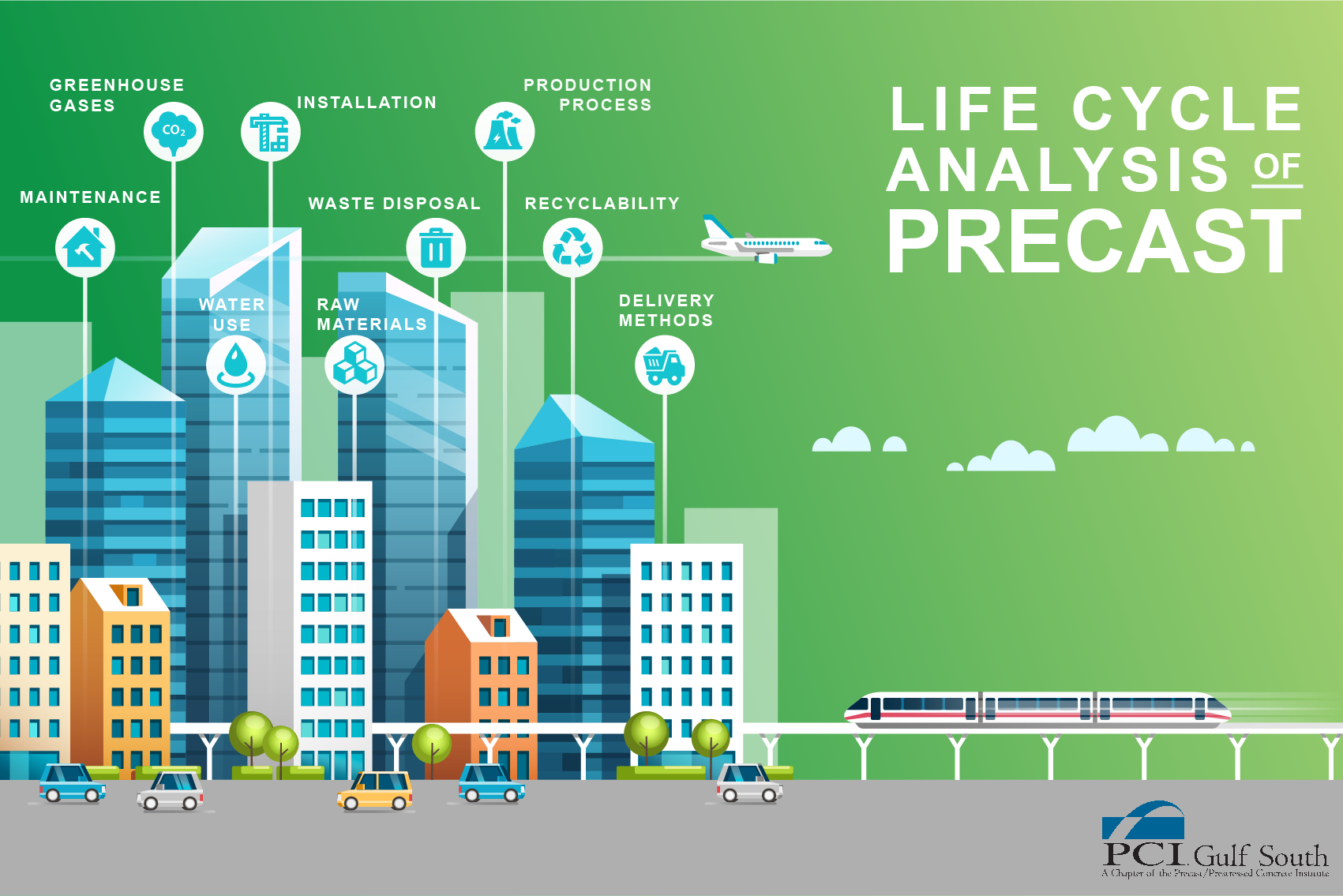

Precast concrete is unique among building materials because of its affordability, toughness, and adaptability. By analyzing its extensive life cycle assessment, affordability, resilience, and environmental sustainability, we reveal its significant influence on contemporary building methods and infrastructure advancement.

In the realm of educational architecture, aesthetics play a vital role in creating inspiring learning environments. Among the myriad of construction materials available, precast concrete stands out for its versatility and potential to enhance visual appeal.

In the world of construction, one advantage oftentimes put towards the bottom of the list of benefits of using precast is soundproofing. Whether its a commercial structure or a residential building, precast can provide soundproofing so all occupants feel comfortable in their individual spaces.

Among the many building materials that are accessible, precast concrete is a reliable option for creating the framework of sturdy infrastructure. Precast concrete has several uses, from unmatched durability and quick construction to strict quality control and environmentally friendly methods.

Construction teams use prefabricated components more often to expedite the building process and provide the project owner with the desired functionality. Two popular types of prefabricated commercial building materials are tilt-up and precast construction. Is one better than the other, and where should each be used? As experts in the precast/prestressed concrete industry, this is how we see it.

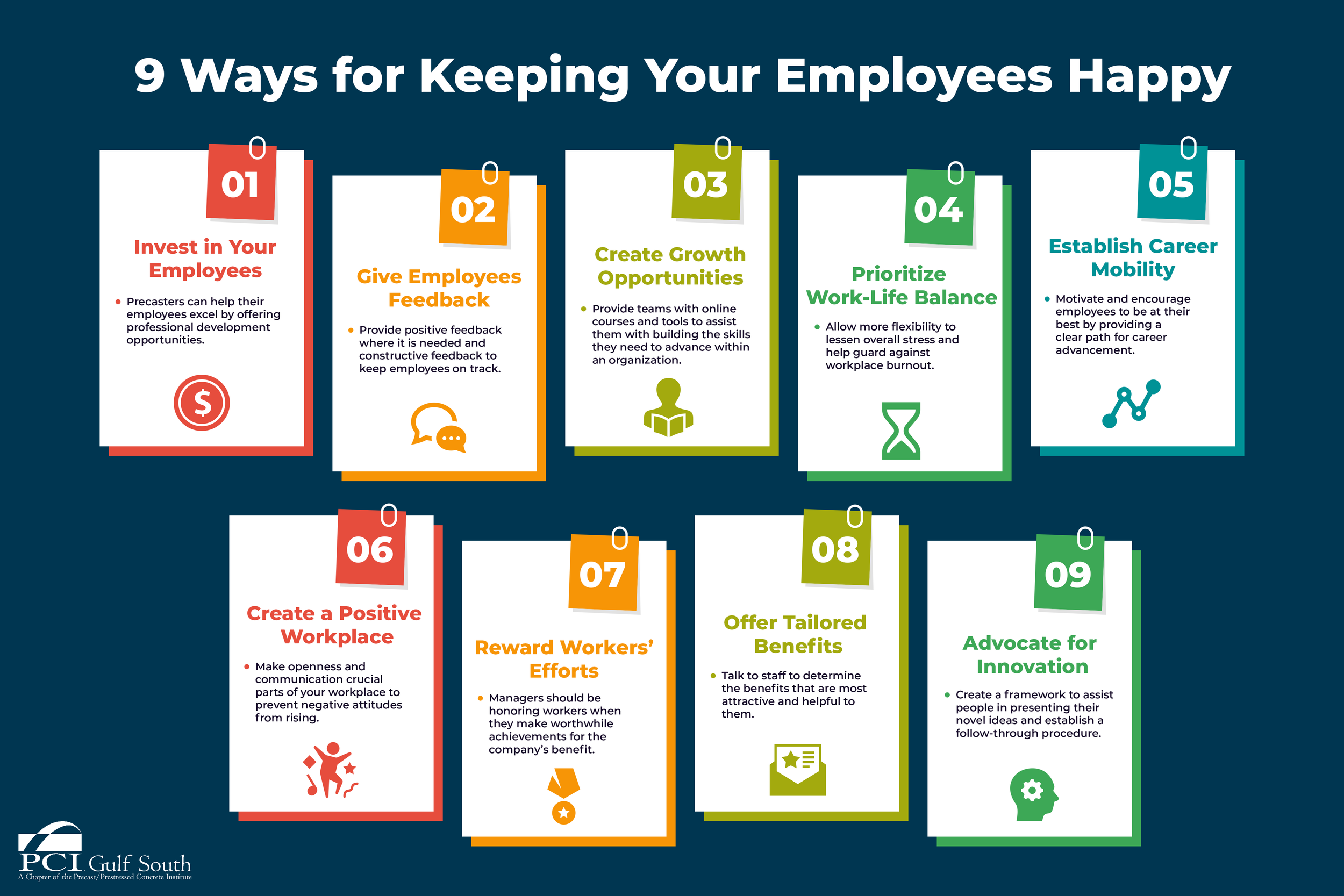

Any precast producer will find it challenging to find competent and motivated people in today's competitive labor environment. How can you differentiate your business from the competition and persuade potential hires that you are the right fit?

Buildings require a long-term vision for their economic, environmental, and social obligations in order to be truly sustainable. By employing environmentally friendly building materials like precast concrete, developers may accomplish this long-term vision of sustainability.

Any project involving the building of concrete will profit financially from using precast concrete. For less money than having concrete cast on-site, you can use precast for roofs, walls, floors, beams, columns, and just about any other feature of a construction.

The second semester of a student's senior year is not the appropriate time to begin developing career-ready students. Students should be focused on their future throughout their college career, and precasters can help them with this preparation. By offering valuable resources and engaging content, precasters can help guide the next generation of precast workers to help improve an already weakened workforce.

A range of intriguing ideas has been put up to deal with the trash that already exists in an effort to recover part of the resources and embodied energy that went into creating 21st-century items. Urban mining is one of these practices.

Architects and designers must anticipate and prepare for construction efficiency throughout the drafting process. Governmental, local, and environmental rules frequently limit their options. Precast concrete components are used frequently when building new infrastructure projects, and their ability to adapt is only one of the reasons why. They also require little to no maintenance and are long-lasting and dependable.

For a precast manufacturer to succeed, its employees must be happy. However, popular methods for increasing happiness are out-of-date. The secret to happiness is no longer getting raises and bonuses.

To get precast to a job site in one piece it is moved from the plant to the yard, the yard to the truck, and the truck to the site to be transported. Precasters must adhere to best practices to maintain the product's quality throughout the various phases of transportation.

When a design team engages a precaster for "design assist," they typically intend to procure precast concrete early in the design process to take advantage of the precaster's knowledge and recommendations to choose the most effective techniques, sizes, finishes, etc. and maximize efficiency across the project.

The employee lifecycle is an organizational technique that illustrates how employees interact with the firm they work for. Knowing what each stage of your employees' experience should bring during their time at your precast company will help enhance their overall experience and keep more employees on longer.

The United States' intricate network of vital infrastructure sectors aims to ensure that our country runs smoothly and its residents are safe. Precast concrete building products address a demand in the ongoing endeavor to safeguard these important infrastructure sites.

As extreme weather events become increasingly common, storm shelters are becoming more crucial across the US. In particular, hailstorms, tornadoes, and dramatic temperature swings have increased in the southern part of the US over the past few years.

Precast, as an enclosure system, provides a distinct advantage over other building materials. Precast walls act as both the structural support for a structure and the component that provides the building’s insulation.

At current rates, global carbon emissions are 36 billion tons annually and rising. With a new focus on reducing carbon emissions to help counteract climate change, the precast industry has begun focusing on improving their processes and educating design professionals on the sustainability that concrete can bring in the long-term.

Through its numerous design benefits, precast can be the go to solution for clients looking to meet sustainability goals and reduce their impact on the environment.

Regardless of the design or product being produced, all precast building materials get their start in a manufacturing facility at the hands of highly skilled producers. The “day-in-day-out” production process is shrouded in a blanket of safety protocols intended to minimize or eliminate worker injury.

Labor shortages are wreaking havoc across the nation. The precast manufacturing industry, along with other industries, is actively taking steps to address the issue while consistently maintaining a reputation for high quality. A solution has been found with the adoption of automation.

As one of the most widely used precast components in North America, the double tee is a versatile and cost-effective precast product that can be used for a variety of projects. But what is the double tee and what makes this precast component so popular?

Residential projects can make use of precast to meet their high-performance goals. From single-family homes to large-scale condos, precast is the right choice for constructing residential facilities.

Ultra-High Performance Concrete or UHPC is a type of concrete that has steadily grown in popularity due to its increased durability and strength over traditional concrete. The US Army Corps of Engineers first used UHPC in the 1980’s, but it wasn’t until 2000 that it became commercially available in the US.

One of the missions of the PCI Foundation is to help support and fund precast studios at universities across the country. Studios are important tools to help future engineers and architects learn what precast is and the benefits it can bring to projects they will design in the future.

Because concrete has a higher density, it has the capacity to absorb and store larger quantities of heat than other materials such as wood and gives structures increased thermal mass.

Because of its resiliency, precast is often used in FEMA shelters and when used in schools, can create a dual purpose for the facility by enabling it to act as a storm shelter for the community.

Athletic facilities are unique structures in the fact that they need to house thousands of people for major events sometimes multiple times a week while lasting through years of continued use and being exposed to the elements.

Precast provides a building solution that K-12 schools can utilize to create modern, low maintenance renovations to existing buildings. Precast structures have an adaptable and versatile design capability that can be blended with existing structures while providing safe and durable spaces for students.

Historic schools face challenges when they need to expand or adapt. This is where the versatility of precast is the perfect solution!

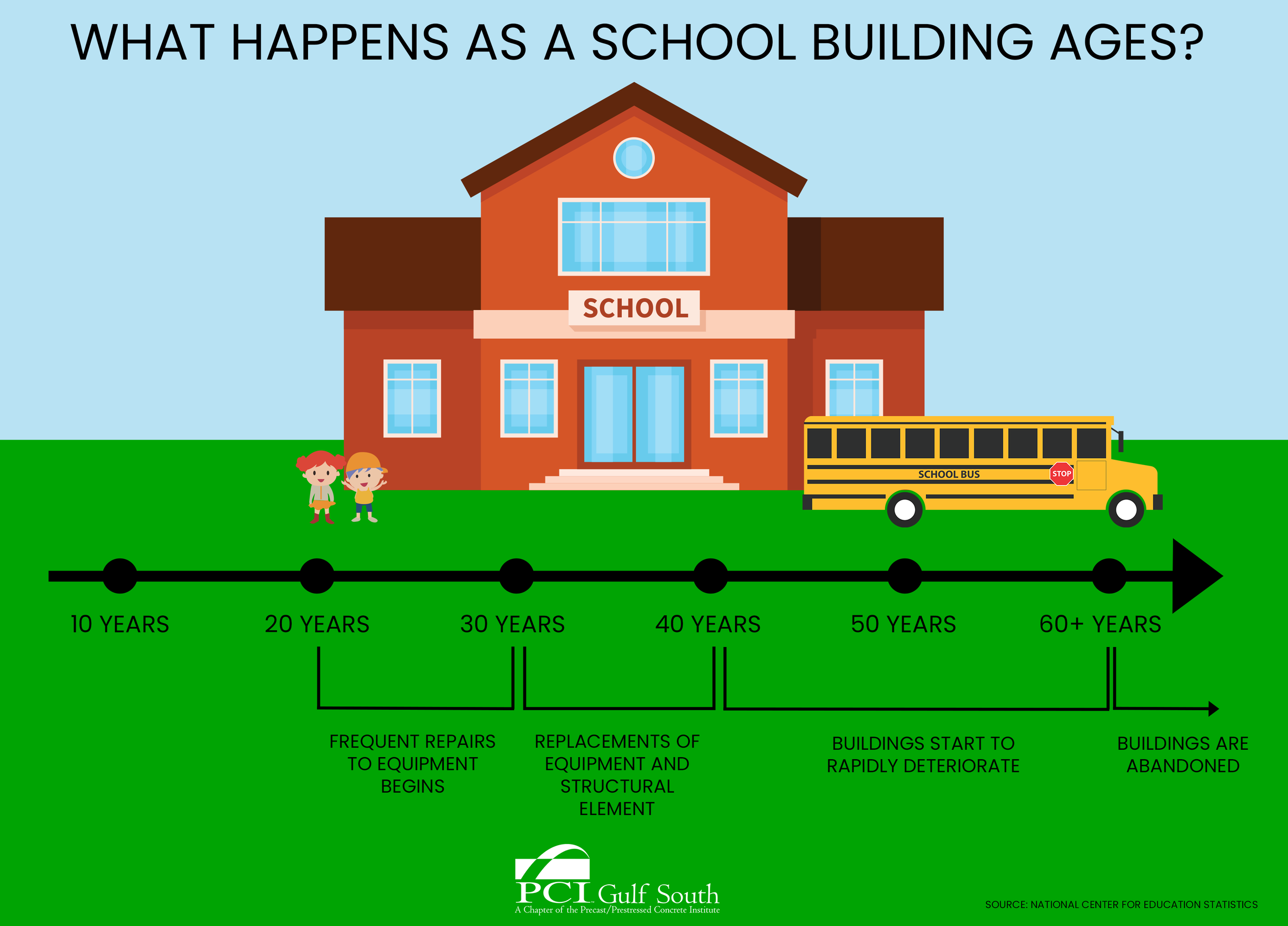

School facilities constructed with precast require less maintenance in the long term and are smart investments. Boasting numerous advantages, precast limits the need for ongoing facilities spending and allows districts to direct more funds toward the education of the student.

The resurgence of precast into the school market started in 2000 when labor shortages placed a crunch on the timelines for school projects. The advancements in precast building products gained a second look of designers because of the lengthy list of advantages precast brings to a project.

So what does LEED have to do with precast? Precast concrete building components possess some of the most inherently environmentally friendly and resource friendly attributes of any building material available.

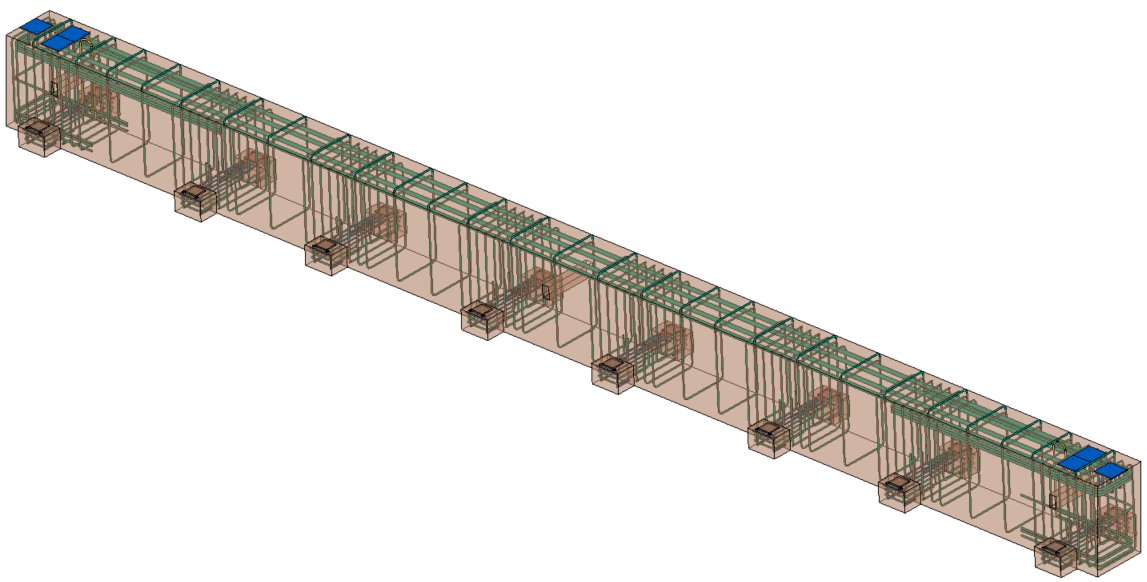

Adding another “weapon to the arsenal” against mounting infrastructure repair/replacement projects across the country, the NEXT Beam was developed by the Northeast State DOT’s in conjunction with consultants and precast concrete producers to serve as a solution to the bridge community’s need for an improved, high functioning beam.

With growing popularity, the construction industry is looking towards the use of precast concrete building components to solve or lessen the issues of working within a small area. Precast concrete as a primary building material for a project brings advantages no other material can match.

In the erection of a precast structure, connections are the “glue” that keeps it all together. As such, there is a vast array of connections available to meet the individual requirements of the project.

Operating a profitable precast concrete plant hinges on the ability to move product through the facility in a timely manner.

University level education of future designers and engineers is crucial to the continued growth of the precast concrete market. As future industry professionals become masters of their trade, the investment that has been made in education at the university level is well worth it.

Thin brick is a product that is used during the precast concrete manufacturing process to create the finished look of a fully brick structure at completion.

The innovative spirit behind designers is the driving force that keeps the ball moving forward with fresh and creative possibilities. The precast concrete industry is brimming with talented professionals ready to turn someone’s “napkin drawing” into reality.

One of the best offsite produced materials that can be utilized is precast concrete which adds value, style, and durability to projects.

The ability to participate in a process firsthand creates a level of appreciation that is difficult to achieve through passive learning alone. Recently, the upper-level architecture students at LSU had the pleasure of a hands-on workshop led by industry professional Layne Chastain from US Formliiner.

In basic terms, prestressed concrete is concrete in which high strength steel reinforcement is stretched and anchored to improve the structural capacity.

Life-cycle cost analysis provides a process by which owners and designers can closely evaluate both short and long term costs of a project to determine the most appropriate direction to proceed.

Abrasive blasting, once referred to strictly as “sandblasting” is an optional process commonly employed on precast concrete panels to create an aesthetically appealing appearance.

Fully functioning, safe roads and bridges are vital to the economy across our nation. The US contains over 250,000 miles of “high volume traffic”.

Precast concrete insulated sandwich wall panels have gained in popularity over the years, but some industry professionals are still not very familiar with them.

All PCI plants are certified in one or more of the following categories. Through two unannounced annual audits, PCI plants maintain their certification. PCI plant certification categories are currently undergoing changes to further define the complexity of each type of certification.

The options for building materials are well established, but are you aware of the costs associated with each type and which offers the most economical long term investment?

The recipe for a PCI certified precast concrete manufacturing plant involves a complex list of ingredients. Being granted the “PCI certified” seal of approval is not something that occurs by simply paying a fee or joining an association.

One of the most productive ways to keep a precast plant organized is through the implementation of Lean manufacturing methods. The core concept of Lean manufacturing is to reduce waste from the manufacturing process and improve efficiency by utilizing the input of pant personnel to provide input into possible improvements.

A bird’s eye view is an invaluable tool on a construction jobsite. Through the use of drones, the building industry is reaping the rewards of this high-flying technology.

Employee turnover is one of those expected and unavoidable facets of running a business. Although it’s experienced by most companies with some regularity, if you find you’re consistently “on the hunt” for new employees, you need to take a serious look at what’s causing the rotating door at your workplace.

General contractors often have the ability to influence owners/financiers to choose particular building products when tasked with a new construction project. From the contractor’s point of view, delivering a quality project, under budget and on time is paramount to customer satisfaction. That’s a mighty big order that becomes more achievable with the use of precast concrete components and/or systems.

As practical, versatile and cost effective as concrete is, it suffers from one not so appealing characteristic. Concrete requires the use of cement and cement production is a huge producer of carbon dioxide.

The construction and demolition industries are making impressive strides toward combating the excessive amount of debris being deposited into landfills. Currently, at least 25% of all solid waste finding its way to landfills comes in the form of construction/demolition waste with concrete debris comprising 70% of that amount.

Every industry evolves with the creative genius of its leaders. Often times, a recurring problem or difficult situation forces management to look for a better way. Such is the case in the precast concrete industry.

Driven deep into the earth and often unseen, lies one of the most durable and economic foundations produced in the precast concrete industry...piles.

Time is money. When you are talking about a big bridge project, a big timeline or extended construction schedule equates to big money. With the increasing amount of crumbling infrastructure scattered across the US, innovative solutions such as Accelerated Bridge Construction (commonly known as ABC) began to be used more by contractors building bridges.

The steady migration of people toward the water has resulted in densely populated areas at very low elevations. Fast forward to an active hurricane season and you have a cocktail for disaster.

The dwindling skilled workforce has left many industries scrambling for needed workers. Especially hard hit is the construction field and the many trades associated with building and development.

For every product manufactured, there are appropriate and responsible applications where they really shine. Pushing the limits past intended purposes for the sake of saving money and/or time isn’t wise and can be potentially dangerous. Such is the case with the proposed use of timber and timber-related products to construct tall buildings up to heights of 18 floors.

School building construction using precast concrete is undoubtedly becoming more popular. Over the past few decades, there has been a significant increase in the use of precast concrete components for various public buildings. This trend has a number of causes, and administrators and builders who are designing new schools can learn a lot from it.