Thinbrick and Precast

Thin brick is a product that is used during the precast concrete manufacturing process to create the finished look of a fully brick structure at completion.

First impressions leave a lasting impression. Precast concrete has the ability to leave a stellar first impression due to the versatility of the product. One such “version” or identity precast concrete can take is the look of brick.

Thin brick is a product that is used during the precast concrete manufacturing process to create the finished look of a fully brick structure at completion. Thin brick is literally a THIN BRICK veneer. It is a product that does not have the same dimensions as a typical brick but instead is the “face” of a brick. During the manufacturing process, a liner is laid down first and filled with the brick pieces. The concrete is then cast on top of the brick. After the panel is raised up, the liner is pulled away. The concrete acts the mortar between the thin brick veneer pieces and creates a strong, beautiful brick-look wall panel.

The use of clay product-faced precast concrete offers an economical solution to the traditional all brick structure and offers the same beauty with improved life cycle costs as noted in the PCI Journal report by Sidney Freedman.

Applications

Endicott brick is an industry leader of thin brick products that allow for a variety of options with aesthetically pleasing colors and patterns. Below you will see some of the common application processes for thin brick.

Photo via Endicott

How Thin Brick is Created

The process of creating thin brick is just as interesting as how it can be used with precast. Below is a video provided by Metrobrick which shows the whole process of transforming thin brick from raw materials to the final product.

Benefits of Thinbrick

There are numerous benefits to thin brick including:

Uses less raw materials

The scaled down size of each thin brick unit, as compared to a traditional brick, results in approximately an 80% reduction in raw material use while achieving the same finished appearance.

More room for insulation

With the use of thin brick, the wall panel has more available space for increased insulation which translates into a greater R value and better life cycle heating and cooling costs.

Less consumption of natural gas

The push to conserve energy use makes the use of thin brick a smart idea. An 80% fuel savings is achieved by replacing traditional brick with a thin brick product.

Few trucks on road

Transporting traditional brick to a job site is costly and time consuming. Through the use of thin brick, the process is handled in a quality controlled environment with only a small amount of additional labor required and virtually no change in transport costs when the panel is trucked to the project site for erection.

Photo via Endicott

PCI has created Guide Specifications that pertain specifically to the manufacturing of thin brick products that are supplied to precast concrete producers to ensure all products meet PCI standards.

Project Examples

Jackson Precast Dudy Noble Field

Jackson Precast used thin-set brick on Dudy Noble Field Stadium at MS State University during renovations to create a stunning, traditional appearance.

Gate Precast SunTrust Park

On-site masons were not needed and the project schedule was able to be accelerated when Gate Precast incorporated thin brick in the SunTrust Park project.

Gate Precast Camp Shelby Operational Readiness Training Center

The Camp Shelby Training Center is an example of reduced fuel consumption and fewer trucks on the road due to the use of thin brick during the manufacturing process of the precast concrete wall panels.

PCI Gulf South Producers/Associates Who Have Experience w/ ThinBrick

Several PCI Gulf South producers are well versed in the use of thin brick for making a statement along the Gulf region and work in conjunction with formliner and thin brick manufacturers to find the correct product to achieve an exceptional end result. You can contact any of the PCI Gulf South members below to learn more about thin brick and how it can be used on your next project.

Choosing a product such as thin brick provides project designers and owners with a large variety of options for creating unique and appealing structures. Along with the exceptional appearance, project savings that result from accelerated schedules, reduced laborers, and reduced use of raw material and fuel make thin brick a winner all the way around.

The Innovative Nature of Precast Concrete

The innovative spirit behind designers is the driving force that keeps the ball moving forward with fresh and creative possibilities. The precast concrete industry is brimming with talented professionals ready to turn someone’s “napkin drawing” into reality.

The innovative spirit behind designers is the driving force that keeps the ball moving forward with fresh and creative possibilities. The precast concrete industry is brimming with talented professionals ready to turn someone’s “napkin drawing” into reality. As is often the case, the conceptual ideas put forth often morph into something completely different when all the options are realized. So what does precast have to offer and how exactly is all that versatility achieved?

Innovations in Design

Formliners & Architectural Capabilities

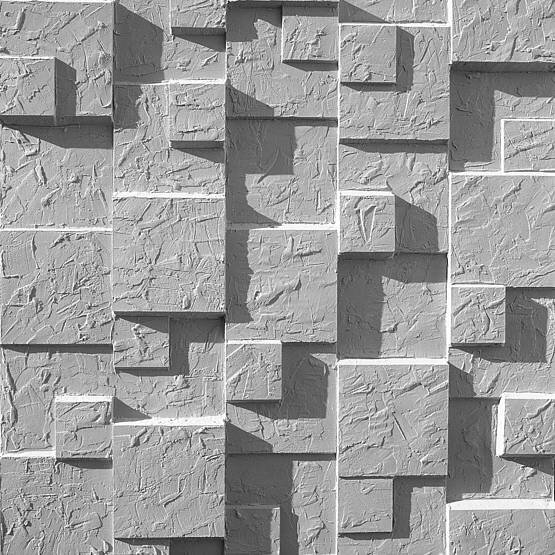

The appearance of the end product is perhaps one of the most important factors in project design. Through the use of formliners, precast concrete takes on any shape or detail imaginable. Formliners act as molds that are filled with concrete. Those molds, or formliners, can be ready-made, standard designs “bought off the shelf” or uniquely designed to provide a “one of a kind” appearance to the concrete product. Coupled with the addition of specialized pigments, aggregates, brick facing, acid etchings etc and you have a highly versatile building material.

US Formliner is an industry leader in providing high quality, reusable form liners and invests time and resources into training the next generation of industry professionals on the beauty and benefits of such an open-ended, innovative product.

Custom Solution for Any Project

Precast concrete has the magical ability to be manipulated into virtually any aesthetic appearance desired. Often times, projects involve “building on to” or an addition to an existing structure. Sometimes, those structures have historic qualities or specialized characteristics that are difficult to replicate. The innovative and adaptable ability of precast concrete to be construed to match existing structures makes it the perfect fit for all types of government, school, military, and community type projects.

Innovations in Design Case Study

Gate Precast created a brand new “old” church in Baton Rouge, LA using some of the innovative possibilities that exist with precast concrete. The finished project has the look of 100 year-old aged limestone, random brick patterns that appear to be hand laid created using custom formliners, and breathtaking Gothic precast arches.

Allen Finfrock, CEO of Finfrock, Apopka, FL has found technological innovations are greatly helping to maximize the productivity of their precast concrete business by saying goodbye to outdated spreadsheets and embracing a vertical integration mentality where the entire design-build team utilizes customized software programs to streamline the process, thereby reducing errors, minimizing change orders, improving schedules, lowering costs, and giving dimensional accuracy to the project that can be viewed and modified as needed. Finfrock recognizes that the construction industry in general has been historically slow to employ technological advancements, but in an effort to remain an industry leader in the precast concrete market, they have embraced and implemented innovative, forward thinking solutions to their business. Read more by clicking on the article above.

The innovative properties of precast concrete are on display with the recent construction of Clybourne 1200 in Chicago, IL. Using the design-build process, the project team was able to collectively create ideas and find solutions to the challenging V-shape structure. The multi-use structure includes retail space, a parking level and residential housing all wrapped in a beautiful and durable structure that even includes a community garden area. Read more by clicking on the article above.

Innovations in Sustainability

Offsite Construction/Quality Materials

One of the key arguments to be made for the use of precast concrete is the benefit of it being manufactured in an offsite, controlled environment. Strict oversight, PCI certified technicians, repetitive seamless processes and arrival at the jobsite ready to erect only add to the innovative nature of this highly adaptable building material

LEED Design/Sustainability

Many attributes of precast concrete products fall in line with the LEED certification often desired and sometimes mandated by project specs. High thermal values allow for lesser HVAC requirements at the onset and minimize heating and cooling costs throughout the life of the building. Other innovations such as self-cleaning photocatalytic titanium dioxide added to the concrete during the manufacturing process lessens the need for cleaning of the building in high humidity locations.

Weather Event Resistances

Innovative designs using precast concrete components create nothing short of a fortress capable of withstanding the strongest of storms and therefore mitigating the need to send piles of debris to the landfill only be faced with rebuilding once again.

The devastation and aftermath of catastrophic storms play out year after year and yet there’s no end to people willing to take the risk to live near the beauty of the beach. So the question becomes, if people are going to continue to inhabit potentially dangerous areas, what can be done to better protect life and property? One part of the solution lies in building structures capable of withstanding natural disasters. Through years of research and development, precast concrete structures have been shown to stand tough to nature’s fury.

Innovations in Sustainability Case Study

Jackson Precast provided precast to the new Robert J Curry Public Safety Center which replaced the old Gulfport Police Station destroyed by Hurricane Katrina. The new complex includes multiple stories for municipal activities and was built with an architectural precast exterior walls and large missile impact window system. The structure was built to meet FEMA 361 design and can act as a hurricane shelter able to self-sustain without power for up to 36 hours.

Innovations in Precast Industry

The age of robotics and AI have led the precast concrete industry into new and exciting territory. Through the use of 3-D printing and highly advanced software such as EDGE and various BIM software products, seamless collaboration, a paperless approach, and problem detection long before the first piece is manufactured is achieved. These incredible cost-saving and time-saving innovations allow for a smoother building process.

How BIM is Changing Precast Concrete

3D Printing and Precast Concrete

Edge^R: Software for the Precast Concrete Industry

Innovations in Precast Industry Case Study

To overcome the inevitable north-facing mildew problems for the LSU Basketball Practice Facility, Gate Precast specified the use of a self-cleaning photocatalytic titanium dioxide admixture, reportedly for the first time in the USA. The goals was an upscale presentation with contemporary finishes that would endure and resist the impact of the adverse climate.

The precast industry is chalk full of examples of how innovative thinking is changing the way we build structures. The desire to maximize safety, minimize use of natural resources, create sustainable structures that last, and construct beautiful buildings we want to live and work in continue to push us to develop better ways to showcase all that is possible with precast concrete.

Offsite Construction and Precast

One of the best offsite produced materials that can be utilized is precast concrete which adds value, style, and durability to projects.

Offsite construction has become popular within the construction industry because of the numerous benefits it can bring to a project. One of the best offsite produced materials that can be utilized is precast concrete which adds value, style, and durability to projects.

What is Offsite Construction?

Offsite construction is defined as any part of the building process that is completed away from the job site and includes both prefabrication and modular construction. Precast is designed and poured in precast plants where the components are overseen by precast manufacturers who adhere to strict quality review processes to ensure quality projects are created prior to arrival at the job site. Mistakes and/or issues are sorted out well before the precast reaches the job site, reducing time spent on site fixing issues and therefore improving construction schedules.

The Benefits of Offsite Construction

Offsite construction is a popular option in cities due to reduced space typically found in urban environments. Precast, specifically, can be erected in tight urban spaces where other forms of construction would not be possible. Also, since precast isn’t shipped to job sites until it is ready for the project, job sites remain free of extra clutter.

Quality can be improved with offsite construction because components are manufactured in environments that operate under strict quality guidelines. PCI has developed strict quality standards that all PCI certified plants are required to follow in order to retain their certifications.

With the introduction of technology, offsite construction has seen an increase in both speed and accuracy. Technology has advanced the industry by minimizing errors that would be difficult to address with onsite construction methods.

Precast concrete also allows for less personnel on the job site. Less people equals less risk of injury and/or accidents. Precast concrete components also helps companies who are struggling to fill positions by allowing them to work with half of the workforce they would need if they were using the cast in place process.

The Offsite Manufacturing Process

Designers and precasters first plan out what is required to create the project elements. This can range from creating precast panels to creating modular structures which contain everything the building needs such as electrical boxes and insulation.

Next, the elements are designed usually with input from precasters who provide necessary expertise to designers of what can and cannot be achieved with precast.

Once the design is approved, the precasters begin fabricating the precast components. This is also the time when formliners are used to create unique shapes and patterns to achieve the desired look.

After the precast has been created, it is shipped from the precast plant to the job site. Pieces can be joined together beforehand or shipped separately depending on the job needed.

Finally, the precast arrives at the job site ready to be assembled. Certified precast erectors are responsible for erecting the precast components safely. Precast usually decreases the amount of time needed and helps speed up the construction schedule, sometimes shaving months or years off project schedules.

PCI Gulf South Offsite Construction Project Examples

Biloxi Bay Bridge

Included 1700 precast components which were erected in 16.5 months

New Orleans BioInnovation Center

Erected in a a tight urban environment in a New Orleans, LA neighborhood

LSU Basketball Practice Facility

Precast cladding cut the schedule down by a year and saved $500K in costs

US Formliner & LSU Students Explore the Versatility of Precast Concrete

The ability to participate in a process firsthand creates a level of appreciation that is difficult to achieve through passive learning alone. Recently, the upper-level architecture students at LSU had the pleasure of a hands-on workshop led by industry professional Layne Chastain from US Formliiner.

The ability to participate in a process firsthand creates a level of appreciation that is difficult to achieve through passive learning alone. Recently, the upper-level architecture students at LSU had the pleasure of a hands-on workshop led by industry professional Layne Chastain from US Formliiner. Layne took the formliner instruction up a notch by inviting the future designers to roll up their sleeves, literally, and delve into the process of creating small scale, specialized formliners. The PCI Gulf South sponsored workshop included participants from Dr. Nikloufar Emami’s precast and stereotomy class.

The students were given formliner master molds, each of which depicted a popular material used for building facades. The students were then instructed in formliner design and manufacture while using the molds to create small, multi-use formliners from urethane.

The goal of the workshop was to share with the students the capabilities of concrete for building facades when using these types of formliners. The students were excited to learn of the potential for architects to achieve virtually any exterior appearance from concrete. Also discussed were the topics of commonly used formliners in the industry, creation of custom patterns using formliners and the advantages of using concrete as a durable and aesthetically pleasing alternative to more expensive facades.

After the students had the urethane poured into the molds, the discussion expanded into what factors need to be considered when specifying formliners and which materials are best for precast, CIP and tilt-up applications. The students were interested in cost and lead time necessary for the manufacture of standard formliners versus a custom pattern. The use of concrete and masonry stain to achieve highly realistic depictions of brick, stone, etc was also covered. At a later date, the student will mix and pour concrete samples from the urethane formliners they created in the workshop.

What are formliners?

Formliners are reusable forms and matrices that allow for the creation of patterns such as stone/brick/wood/stucco/abstract designs etc on concrete facades. The creative freedom formliners provide allow for unique product finishes.

Below are some images from RECKLI, partner of US Formliner, which shows a closer look at the different types of patterns possible from fromliners.

How are formliners made?

PCI Gulf South and LSU Architecture Department would like to thank US Formliner in Athens, GA for providing the materials and instruction and assisting in making this workshop possible. I special shout out goes to Layne Chastain for his contribution to this blog. Don’t forget to check out their work to see all the design possibilities of precast and how it can be used to meet your next projects needs!

This story was apart of our September 2019 newsletter. To read more from, click the button below!

The Effect of Prestressing on Concrete

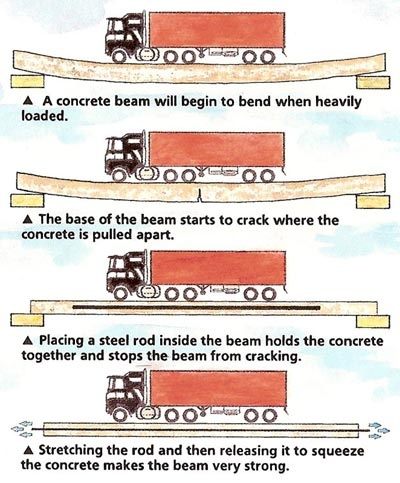

In basic terms, prestressed concrete is concrete in which high strength steel reinforcement is stretched and anchored to improve the structural capacity.

What is PRESTRESSED CONCRETE?

In basic terms, prestressed concrete is concrete in which high strength steel reinforcement is stretched and anchored to improve the structural capacity. The internal stress created by the embedded steel reinforcement greatly improves the performance and service of the product.

Why/when is it necessary to “STRESS” concrete?

In general, concrete does not have good tensile strength, however, it performs well under compression. A traditional analogy often used to explain the concept originated with Dr. Mangel who likened prestressing to stacking books side by side and placing pressure on both ends. The pressure exerted on the books creates so much strength that the books could be lifted as a single unit and could also support great loads on top without breaking apart. The very same concept is repeated with prestressed concrete products.

How does the process of PRESTRESSING occur?

The process of prestressing involves high strength steel tendons or “strand”, typically of low relaxation 270 kps type steel to be pulled to a predetermined, engineered spec and then concrete is cast over the strand and allowed to harden or cure. The strand is then cut at each end releasing the prestressing force into the product by way of its “bond” with the concrete. The internal force then allows the concrete to span greater distances and be loaded with greater weight.

What are some of the benefits of PRESTRESSING concrete?

Allows for the reduction in mild reinforcement

Aids in controlling cracking

Allows for longer spans in a single piece instead of the need for multiple pieces

Allows for greater load carrying capacity

What are some types of products that utilize PRESTRESSING?

Concrete beams

Double Tees

Wall panels

Bridge girders

Concrete piles

Roadway pavement slabs

Take a look at the video below to see an in depth discussion on how prestressed beams are created and work.

Want to learn more about prestressed concrete? Schedule a lunch and learn today and learn how prestressed concrete products can you be used for your next project!

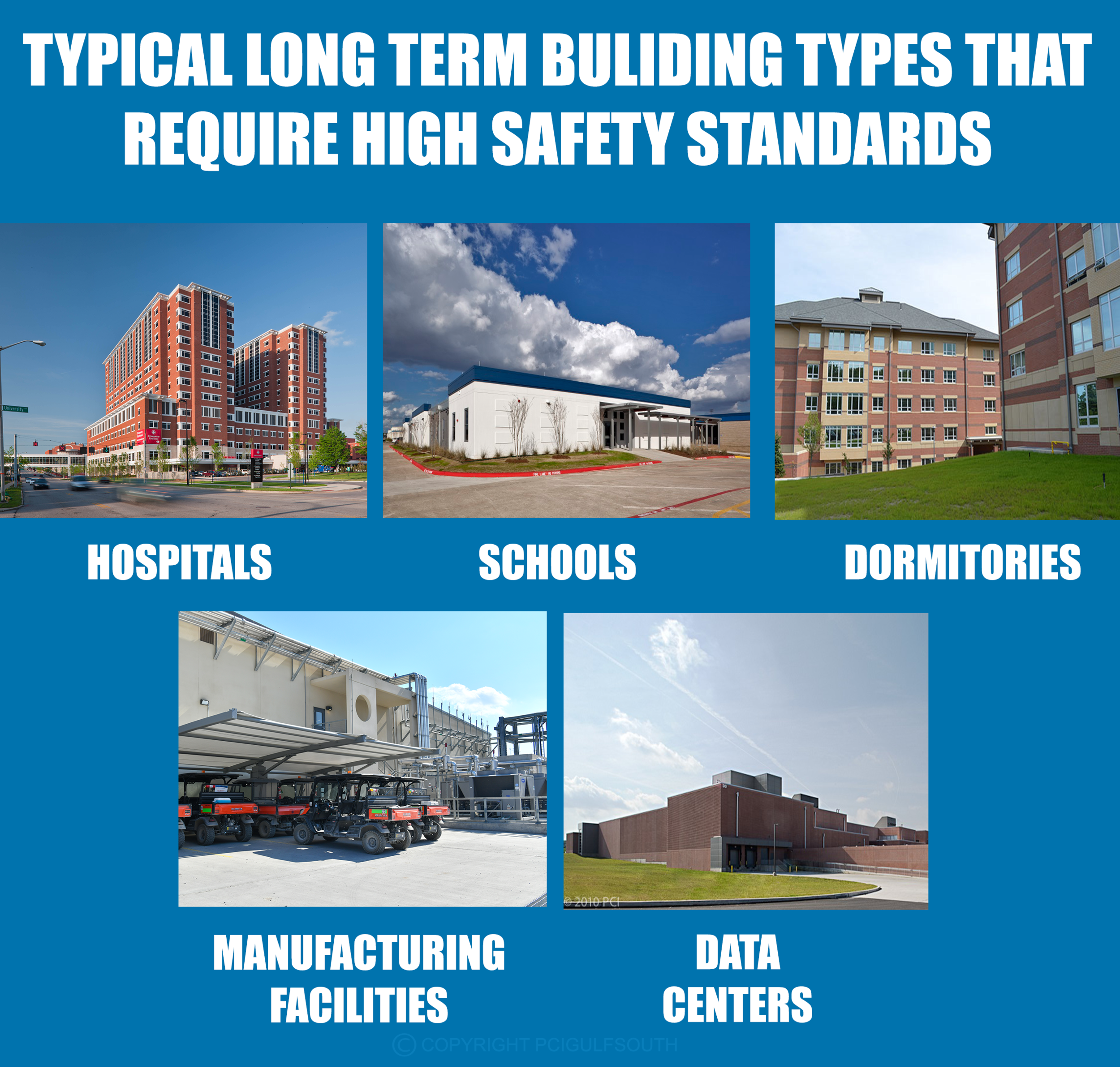

Precast & Life Cycle Cost Analysis

Life-cycle cost analysis provides a process by which owners and designers can closely evaluate both short and long term costs of a project to determine the most appropriate direction to proceed.

Life-cycle cost analysis provides a process by which owners and designers can closely evaluate both short and long term costs of a project to determine the most appropriate direction to proceed ( i.e. material selection, HVAC consideration, etc.). Sometimes, when an owner embarks on a project, they already know that they don't intend to hang on to the building long term. In this case, the goal is to construct the structure in the most cost effective manner possible with limited concern for the future. Other times, owners enter into a project knowing it’s a long term investment that will be expected to perform for decades into the future.

Using the technique of life cycle cost analysis offers owners and designers a window into how the planned project is going to perform and the expected on-going costs over time. Almost always, buildings that are constructed to perform well into the future will cost more upfront. The overall quality is higher and that quality translates into an increased price tag. However, most times over the lifespan or life cycle of the building, the savings that is realized through such things as improved energy efficiency and reduced maintenance costs makes up for the difference of building with lesser quality materials.

Precast concrete is a strong performer when it comes to long term performance and reduced life cycle costs for the following reasons:

Thermal mass: concrete forms the structure and creates a thermal barrier

Initial HVAC system installation can be scaled back

Reduced overall energy consumption (both heating and cooling)

Multi-hazard protections (fire containment, blast resistance, mold resistance)

Higher resale value

Improved insurance rates

Less overall maintenance (higher durability = less costly repairs)

Precast concrete a material well suited for projects expected to stand the test of time. Time and time again, life cycle cost analysis shows that the upfront construction costs associated with precast concrete structures “pays for itself” over time. To learn more, visit www.pci.org

Resources

Whole Building Design Guide by Sieglinde Fuller, NIST, 9/19/2016

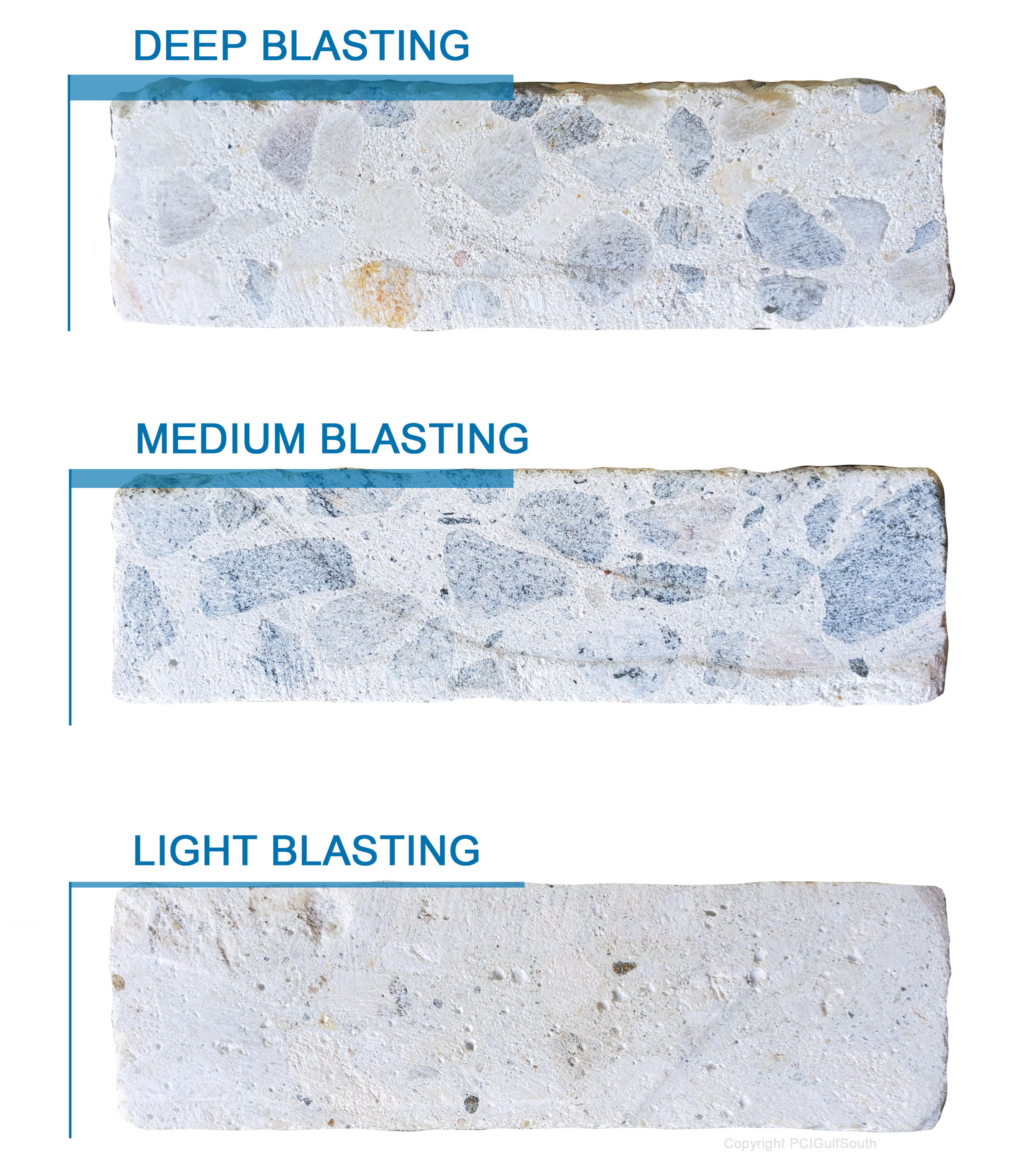

Abrasive Blasting: The Limitless Option for Precast Concrete

Abrasive blasting, once referred to strictly as “sandblasting” is an optional process commonly employed on precast concrete panels to create an aesthetically appealing appearance.

Abrasive blasting, once referred to strictly as “sandblasting” is an optional process commonly employed on precast concrete panels to create an aesthetically appealing appearance. Concrete, in its natural state, cures in various shades of gray. The color of concrete can be altered through the use of dyes or powders. The process of abrasive blasting can also change the color and texture of exposed concrete.

The idea of abrasive blasting is to remove the outer skin or matrix of the concrete panel to expose the different aggregates that exist in the concrete mix. Various depths of blasting result in different appearances/textures.

With each depth of blasting, the aggregates present in the concrete play a greater role in the overall appearance.

Interestingly enough, an array of materials are utilized during the blasting process. Some commonly used blasting materials include:

Sand

Plastic Beads

Steel Shot

Glass

Walnut Shells

In conjunction with other finish options, abrasive blasting offers the limitless options designers and owners seek for their projects. Visit our Aesthetic Versatility page to see to a sample collection of the different appearances that can be achieved with precast and get access to our Color and Texture guide.

Precast Concrete Pavement Is A True Workhorse

Fully functioning, safe roads and bridges are vital to the economy across our nation. The US contains over 250,000 miles of “high volume traffic”.

Fully functioning, safe roads and bridges are vital to the economy across our nation. The US contains over 250,000 miles of “high volume traffic”. High volume being defined as over 50,000 vehicles per day. It stands to reason that repairs or replacements of those high volume roadways create major issues when they deteriorate. Typically, an asphalt road surface has a lifespan of 10-15 years while a concrete road service lasts 40 or more years. The increased lifespan of 3 to 4 times longer makes concrete a logical choice for high traffic areas.

Take a look at the video below that shows the heavily traveled I-5 North Highway in Los Angeles. Through the use of precast concrete replacement slabs, improvements to the road were made at night to minimize disruption to commuter traffic and improve worker safety. The sections that were replaced will require no further work for a very long time. If the I-5 Highway had been repaired using traditional asphalt pavement, the road would’ve been closed for an indeterminate amount of time and would have a lifespan of only ¼ that of the concrete replacement slabs that were employed. It’s a “get in, get out” process because the slabs arrive at the site ready for installation. The offsite manufacturing process minimizes disruption and ensures top quality product each and every time all while maximizing worker safety.

Grouting panels

Load Transfer Dowels

Typical Joint

Advantages of PCI certified precast prestressed concrete replacement slabs:

Faster construction cycle due to offsite manufacturing in a quality controlled environment

Less disruption (if any) to the daily commuter who typically uses the road

Less construction staging area creates a safer work atmosphere for workers

Projects can range from 1 slab to large multi-lane projects

Ready for immediate use

Weather plays little if no disruption to the installation process

Smaller work crews are needed

Lower life-cycle costs over the life of the roads

Vehicles use 15-20% less fuel of concrete roadways

Concrete roads are more resistant to fuel leakage from cars and extreme weather.

The argument can be made that asphalt roads are less costly and that asphalt can be recycled using a melting process. Asphalt roads are easy to repair using patches or a relayering process. However, asphalt is not the “workhorse” concrete is. Heavy rain and extreme weather take a toll of asphalt. Also, the petroleum needed to produce asphalt, as well as the process itself, is less environmentally friendly than the production of concrete. When considering how to most effectively use precious infrastructure dollars, PCI certified precast concrete replacement slabs is the best solution for high volume roadway under constant use.

Sources: www.brighthubengineering.com

An Introduction to Precast Prestressed Concrete Insulated Wall Panels

Precast concrete insulated sandwich wall panels have gained in popularity over the years, but some industry professionals are still not very familiar with them.

By Edward Losch, PhD, PE, SE, RA

Precast concrete insulated sandwich wall panels have gained popularity over the years, but some industry professionals are still not familiar with them. Reasons for their increased use in place of more traditional materials include:

Speed of erection: A typical warehouse can be erected in a week. Cold weather is not a factor, since the panels are cast in a temperature-controlled environment and shipped to the site when needed.

Design flexibility: The casting procedure allows for a great variety of finishes and patterns, including inset brick, stone and abrasive blasting.

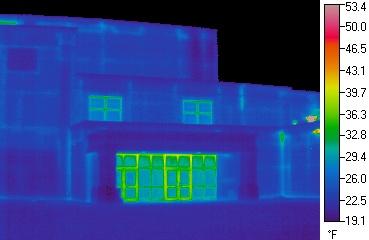

Thermal efficiency: Edge-to-edge, top-to-bottom rigid insulation can be used within a relatively thin wall, providing a high effective R value. The thermal mass of the concrete provides an added benefit by slowing heat transmission through the wall, flattening out temperature swings. (Figure 1)

Figure 1: A thermal image of a standard “stick built” wall (left) and a precast wall (right). Blue shows areas of less thermal transference.

Used in conjunction with ASHRAE 90.1, a building’s thermal performance can actually double using precast wall elements. This in turn can reduce the size of HVAC units needed.

Competitive cost: Precast concrete wall panels can be a cost-effective alternative to masonry or other hard wall systems and does not require as much labor as other systems.

What is a precast concrete sandwich wall panel?

A typical panel has two outer concrete layers, or “wythes”, separated by rigid insulation (Figure 2), and is cast in a long-line form in a plant (Figure 3). One or both wythes are usually prestressed to reduce cracking and improve performance (Figure 4).

Figure 3: Placing concrete for the exterior Wythe.

Figure 4: Installing strand.

The panels are trucked to the job site and erected with a crane (Figure 5 A & B).

Figure 5a: Panels being shipped on 45-degree racks.

Figure 5b: Panels being erected using a “2 part” line.

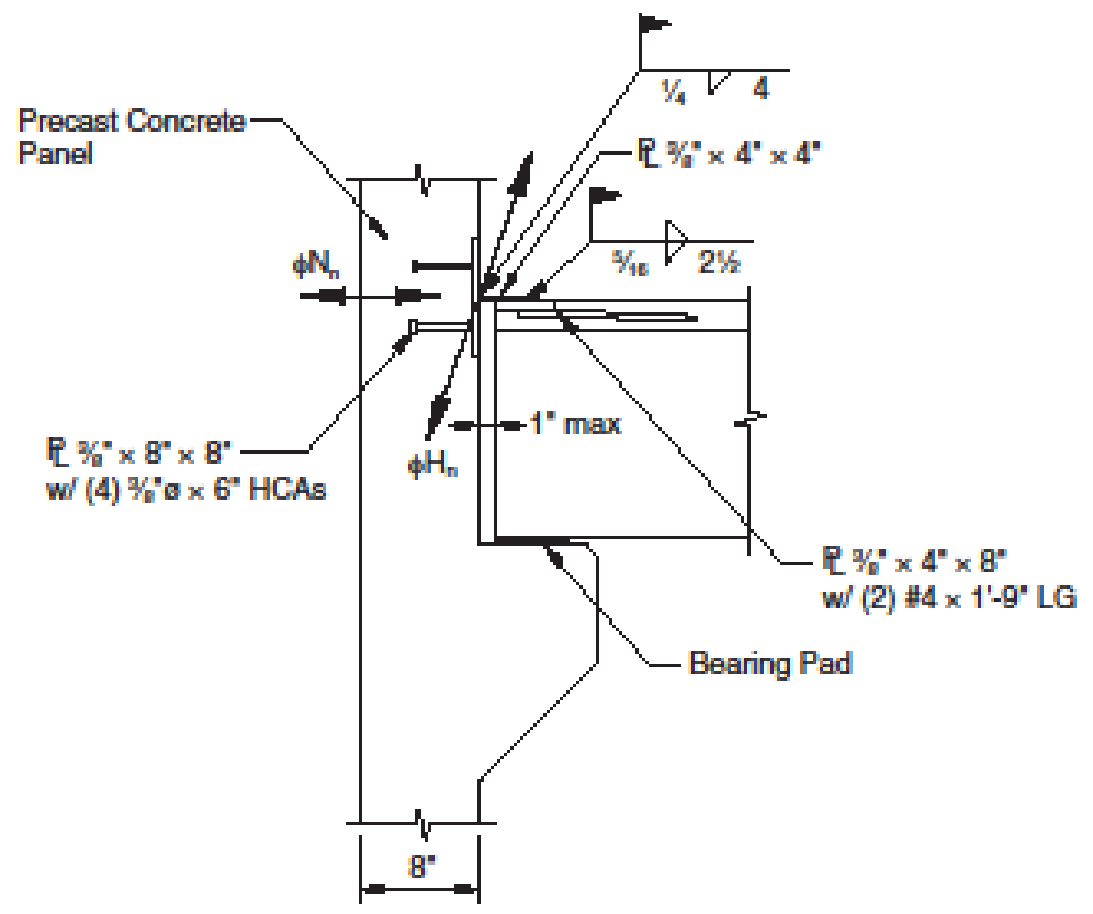

Panels can carry roof and floor loads or just act as cladding (load-bearing vs. non-loadbearing, (Figure 6A, B and C).

Figure 6a: Floor loadbearing.

Figure 6b: Roof loadbearing.

Figure 6c: Non-loadbearing wall panel connection.

Different types of panel designs

Non-composite: In non-composite panels, the concrete wythes act independently (Figure 7). This design is typically used when a high insulation value is required, such as for a cooler or freezer building. The wythes are isolated by high-performance rigid insulation and are connected together solely by thermally, non-conductive pin connectors. The pins are made of either a fiberglass and vinyl ester or polypropylene plastic or other non-conductive material. The interior structural wythe is usually much thicker than the exterior face wythe.

Fully-composite: In fully-composite panels, the wythes act together as a unit for full horizontal shear transfer. A typical composite panel is eight times stiffer, can take three times the stress without cracking and has twice the ultimate strength of a non-composite panel of similar thickness. Composite panels are typically less expensive than non-composite panels, primarily because they can carry more load and can be made taller and thinner. The inside and outside wythes are usually stressed with prestressing strand and made of equal thickness in order to minimize internal strains. (Figure 8) Sometimes, the panel is made solid below the floor line and above the parapet (outside the building envelope) to help with composite action.

Unlike non-composite panels, composite panels often bow outward when exposed to direct sunlight, due to the temperature increase and subsequent expansion of the outer wythe. This characteristic is normal but should be taken into account if panels are attached to, or butt up against, an intermediate floor near mid-height.

Partially-composite: Partially composite panels provide less than full shear transfer between wythes. They behave in a manner in-between composite and non-composite. The degree of composite action is determined by load tests performed by an independent testing lab. Proprietary partially-composite wall systems are now available which combine the high insulating value of non-composite panels with the strength and slenderness of composite panels. This is

accomplished using nonconductive truss (Figure 9), grid or individual connectors between the wythes for shear transfer. Partial composite action provides sufficient strength for most applications.

It is important to keep the distinctions between panel types in mind when determining a standard wall thickness for a project. Since the panels are cast in a form that is usually several hundred feet long, the thickness should ideally be the same for all the panels on a particular project to avoid excessive set-up costs. Occasionally, a designer will select a panel thickness based on the assumption of full composite action, but then insist on thermal performance that can only be achieved with a thicker, more expensive, non-composite design. Working with a local precast manufacturer to estimate a panel thickness can ensure design requirements are met with the most economical panel.

How are they manufactured?

Solid wet-cast: The panel face that is exposed to weather is usually cast down-in-form. The outside face, therefore, has a steel form finish. The inside face can have a float finish (rough) or hard trowel finish (smooth). Reveals and form liners can be applied to the form to add architectural interest (Figures 10 A, B and C).

Figure 10a: Ribbed formliner before casting.

Figure 10b: Reveals on the casting bed.

Figure 10c: Wood formliner texture after casting.

Projections from the face, such as a bullnose or cornice, can be cast separately and connected to the panel face later (Figure 11 A and B), or, alternately, formed out of polystyrene insulation and Dryvit.

Figure 11a: Typical “Bullnoes”.

Figure 11b: Typical Cornice.

Hollow-core wet or dry-cast: The hollow-core wythe is placed down-in-form

and is the main structural wythe for this non-composite system (Figure 12). The top wythe is thin, non-structural and serves as the outside face exposed to weather. Plastic pins or stainless steel “C” hooks anchor the top wythe to the bottom wythe. Wet-cast hollow-core uses inflatable diaphragms, insulation, or gravel to create the voids. Dry-cast hollow-core uses a zero-slump concrete mix and the “plank” is extruded from a machine-like pasta. Window and door openings are typically saw-cut in the field.

Figure 12: A standard hollowcore insulated wall panel (above) and wall panels in service at a dock location (right).

Dimensional considerations: For prestressed panels, the panel width is limited to the precaster’s long-line form width, as well as shipping restrictions. Panels more than 12 feet wide may require special handling (Figure 13), and panels wider than 14 feet can be a challenge to ship by road, due to the lane width and minimum bridge height along the chosen route. Individual panel heights are more flexible, with possible lengths of 70 feet or more. Standard flat bed trucks can carry panels up to 40 feet long, with a total cargo weight limit of 40,000 lbs. For example, a standard truck could carry two panels with a unit weight of 75 psf and dimensions of 8 feet wide by up to 33 feet long each. There is a major cost advantage to being able to ship two panels in one load, if feasible.

Figure 12: Oversized panel on a 45-degree rack.

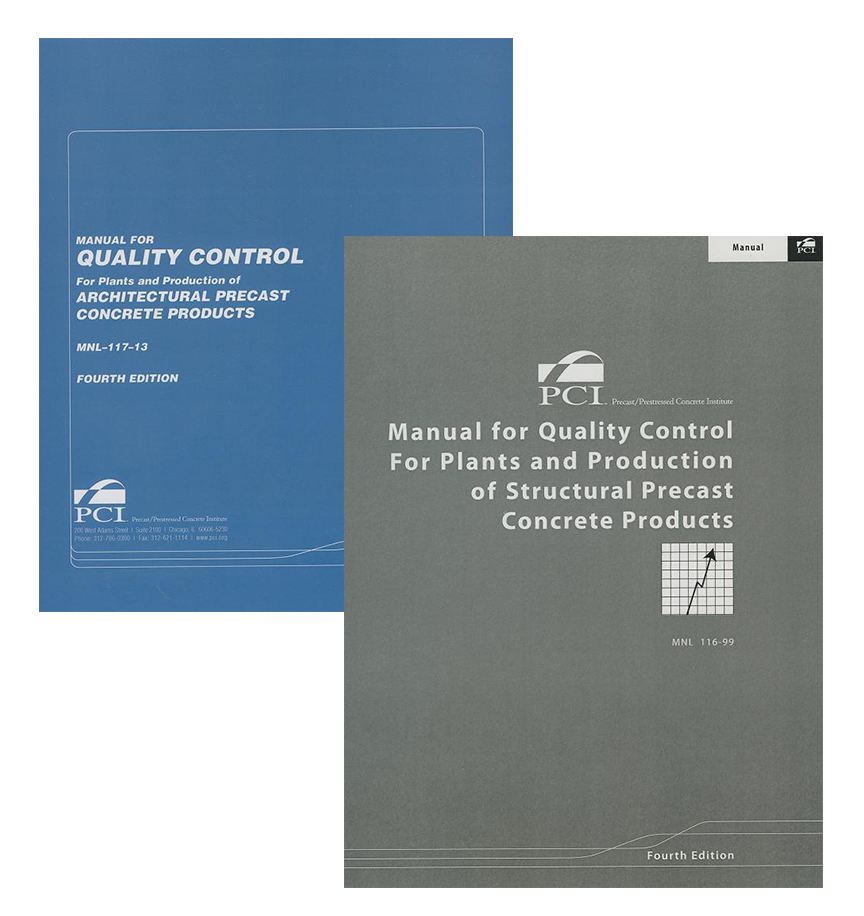

Manufacturing tolerances: Specify the Precast/Prestressed Concrete Institute Guide Specification, PCI MNL 116, “Manual for Quality Control for Plants and Production of Structural Precast Concrete Products”. Although PCI MNL 117 is the guide of choice for architectural precast products, precast/ prestressed wall panels are large and often load-bearing, so it may not be practical to meet all of the finer tolerances in MNL 117. In most cases, MNL 116 is the appropriate standard to use for this product type.

How are they designed?

Figure 14a

Figure 14b

Design responsibility: Due to the complexity of precast/prestressed concrete design and differences in standard products supplied by various precasters, the design responsibility for the precast components is usually taken by a licensed structural or professional engineer hired by the precaster. If the building has precast exterior walls only, then the lateral load calculations are usually done by the Engineer of Record (EOR). The EOR calculates and notes all loads applied to the panels on the contract structural set. The precast engineer is then responsible for the panel designs. For an all-precast building, such as a parking deck, the lateral loads may be calculated by the precast engineer. The EOR would then design the foundation only, using loads provided by the precast engineer. The design responsibilities of the precast engineer should be spelled out in the General Structural Notes to avoid conflict.

Structural planning: Use repetition to minimize the number of different forms required to produce the wall panels. Stick to a consistent panel width; 12-foot widths are usually most economical and minimize the number of vertical caulked joints. Adjust the bay spacing to match a multiple of the panel width so that

connections occur at the same place on the panels. For example, use 36- or 48-foot bays for 12-foot wide panels, and 40-foot bays for 10-foot panels. Panels with “punched” openings (Figure 14a) are easier to handle than L or C shaped panels (Figure 14b).

Anticipate the erection sequence. It is preferable for the precast concrete products to be erected all at one time. If the precast erector has to come back later to place additional panels supported by steel framing, then it may be desirable to convert this steel framing to precast. Alternately, the precast erector may be able to erect a few steel beams to avoid another “move-in”.

Handling loads may be most critical: The forces a panel experiences when stripped from the form, then bounced around on the truck to the job site and then tripped up into place, usually exceed any in-place design loads due to gravity, wind or seismic. This is a good load test for a panel; if it survives the trip, it will surely do fine in service. Lifting inserts are placed in the panel face and edges at locations designed to minimize stresses.

Brace design: For load-bearing panels, temporary steel pipe braces (Figure 15a) are usually anchored to augured or mass concrete blocks called “deadmen” (Figure 15b). Sometimes a continuous temporary strip footing is poured, and braces are anchored to them. Newer technology has been developed that uses helical anchors to secure braces. (Figure 15 C)

Figure 15a: Typical pipe braces.

Figure 15b: “Deadman” concrete block.

Figure 15c: Screw in helical anchors.

Connection design: Most precasters have a library of standard connection designs that they are comfortable with. It helps to incorporate the standard connections used by the precasters who will be bidding a particular project. Many precasters will put a clause in their contract which gives them the option to substitute

their standard connections for those shown on the structural contract set. These connections will be designed by the precast engineer. Some typical connection types are shown in (Figures 16 – 19)

Figure 16: Typical recessed panel to panel connection.

Figure 18: Typical recessed corner connection.

Figure 17: Hanging panel connections.

Figure 19: Typical panel “slip” connection.

Design software: The author has developed specialized software specifically for precast concrete sandwich wall panel design and analysis. This software has been in use since 1994 and has become the industry standard for this product type. See www.LoschSoft.com for more information.

For further information: The author recommends the Precast/Prestressed Concrete Institute report, “State-of-the Art of Precast Prestressed Concrete Sandwich Wall Panels”, 2nd Edition (Publication JR 500, available at https://www.pci.org/ItemDetail?iProductCode=JR-500). (Available as a free PDF Download)

About the author: Ed Losch is both a licensed structural engineer and architect with a PhD in Architecture from the University of Southern California. He is an active member of the Precast/Prestressed Concrete Institute (PCI) and past Chair of the PCI Precast Insulated Wall Panels Committee.

Pictures courtesy of PCI

PCI Plant Certification Categories

All PCI plants are certified in one or more of the following categories. Through two unannounced annual audits, PCI plants maintain their certification. PCI plant certification categories are currently undergoing changes to further define the complexity of each type of certification.

All PCI plants are certified in one or more categories. Through two unannounced annual audits, PCI plants maintain that certification. PCI plant certification categories are currently undergoing changes to further define the complexity of each type of certification. Specifically, Category A is being further delineated in four levels, from the current two level format. The purpose of expanding Category A will allow specifiers to more accurately select the appropriate category to match project expectations. The goal is to have the new classification in place by July 2020.

For further information, visit www.pci.org

Edge^R : The Software Solution for the Precast Concrete Industry

The EDGE^R platform provides the precast concrete industry with a comprehensive solution for project design, estimation, production, erection, and much more. EDGE^R utilizes the world’s most preeminent graphics software, Revit, to facilitate the creation of detailed 3-D models which can be translated into accurate bills of materials and shop tickets, allowing a more seamless workflow from the estimation phase through the erection phase. In combination with EDGE^ERP, EDGE^CAM, and EDGE^CLOUD, users can optimize all facets of their business.

Five Key Attributes of Edge^R

Modelling

Simple, intuitive, time-saving custom content that cuts down on human error and simplifies the reinforcing process of the model and then translates information for accurate take-offs, drawings and shop tickets.

Project Management

Through an efficient tracking process, Edge^R Ticket Manager accurately determines the number of marks and total pieces, quantifies and identifies elements that have been reinforced, tracks creation of shop tickets and identifies when a ticket is ready to be released to production.

Shop Tickets

Through the use of customizable templates, Edge^R allows the user to quickly generate shop tickets that include appropriate views, bills of materials, title block information and more.

Change Management

Changes made to the 3-D model are automatically reflected on all relevant drawings and tickets. Additionally, updated counts of such items as bricks, embeds etc. occurs.

Schedules

Edge^R provides parameters to customize detailed schedules for the whole project, portions of the project and/or one specific element of the project.

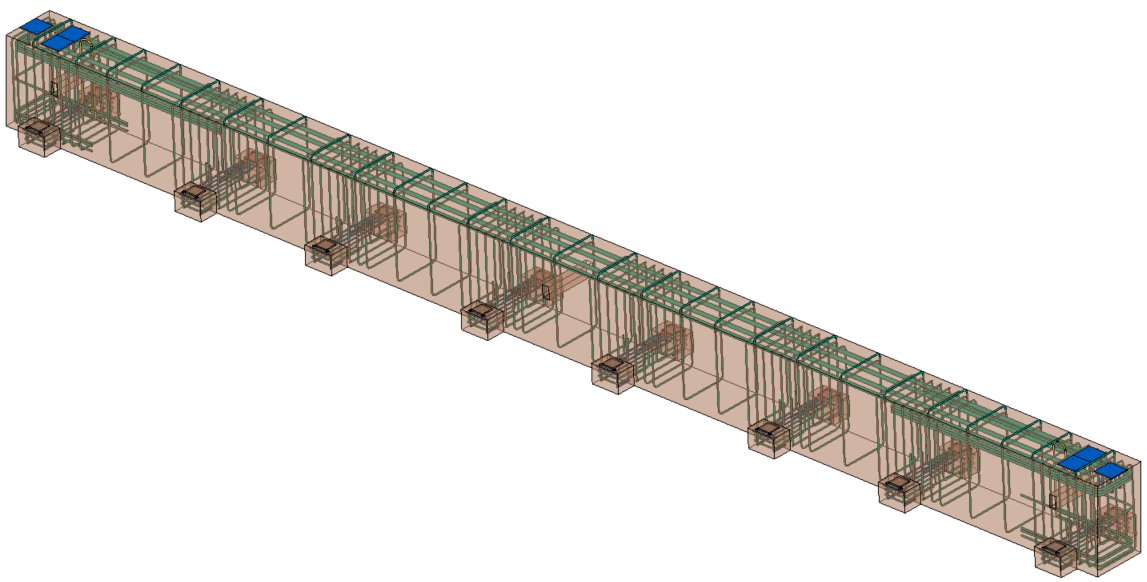

Beam modeled using EDGE^R

Shop ticket generated using EDGE^R for the beam to the left.

EDGE^ERP

The EDGE^ERP solution leverages the user’s model to extract information that can be directly imported into many common Enterprise Resource Planning (ERP) systems. It gathers pertinent information from all elements (such as precast elements, cast in place embeds, loose materials, lifting/handling, etc.) in the model and converts it into a file format which can then be utilized by the user or directly integrated into the user’s ERP system.

EDGE^CAM

Using the existing Revit model, EDGE^CAM makes automation of the production workflow possible. EDGE^CAM extracts information directly from the model and converts it into a file format that can be read by many automated machines. The exported file contains information about finishes, cutouts, rebar, embed placement, and much more. The practical applications include laser projection, bed plotting, automated rebar bending, automated concrete distribution, etc. Supported file formats currently include Unitechnik (UXML) versions 5.2, 6.0, and 7.0 and Progress Group (PXML) version 1.3.

EDGE^CLOUD

The cherry on the top of the cake with this amazing technology is the EdgeCloud factor. Through EdgeCloud, real time information can be provided to production and can be easily accessed on a tablet or PC allowing for seamless communication between engineering and production personnel.

EDGE^R and Virtual Reality

EDGE^R can also be used with designs for virtual reality systems. Below is a screenshot of a component designed using EDGE^R in virtual reality.

Not All Bridges Are Created Equal

An Editorial from Dan Eckenrode, PCI Gulf South Executive Director

The outrage over our nation’s crumbling infrastructure and the cry to fund new bridges and roadways is no secret. As the list of deficient bridges continues to grow, government leaders are being forced to address the issue, as it has a direct correlation to economic progress across the nation. During the recent Alabama Transportation Conference, I learned that there are over 1,200 deficient bridges in that one state alone. Some bridges have been deemed unsafe and closed altogether, while others have been downgraded in loading capacities which means heavy vehicles are no longer permitted to use them. If the bridge isn’t in your neighborhood or on your route to work, you most likely don’t give it a thought. However, when people and businesses are forced to go miles out of their way due to a closed bridge, they start to grumble.

What types of bridges are in use today?

Wooden Bridges: A wooden bridge might include a structure made completely from wood or a structure supported on wooden piles. Either way, wooden bridges are the number one type of failing bridge today.

Channel or “Choctaw” Bridges: These are non-stressed concrete U channel bridges with a span of typically 26 feet that require many units to complete the span. Grout is used where the joints come together. The production of this type of bridge began in the 1960’s and is still used today with some mixed success.

Steel Bridges: As the name suggests, this type of bridge is created from steel.

Precast-Prestressed Bridges: Bridge manufactured components that began around the same time as the previously mentioned Channel Bridges but with greater success and superior product lifespan.

The take-away is...not all bridges are created equal. In an attempt to stretch road and bridge dollars further than ever before, durability and life cycle are two repeating themes. DOT’s across the nation have come to realize that designing with precast-prestressed bridge components will yield the desired results with regard to longevity, safety and cost-effectiveness.

You can learn more about PCI certified bridge products by taking a look at the various resources below.

Think Long-term...Choose Precast Concrete

The options for building materials are well established, but are you aware of the costs associated with each type and which offers the most economical long term investment?

The initial cost associated with the construction of a new building is reason to take pause and consider all material options. Once the building is up and the ribbon cutting is over, the total cost of ownership (TCO) is the ongoing factor that lives on year after year. According to PCI’s Designer Notebook, 90% of the energy used during the life of a building is attributed to heating, cooling and other utilities. (DN-16, page 25) Because these ongoing expenses are unavoidable, it makes good sense and good CENTS to select a building material that is going to effectively save energy. The options for building materials are well established, but are you aware of the costs associated with each type and which offers the most economical long term investment?

No matter what size the building is, where it’s located or what function it serves...it will require heating and cooling at various times throughout the year. There’s one building material that’s been shown to outperform all others in this category and that’s precast concrete building systems.

Let’s face it...precast concrete buildings are excellent at regulating temperature. They’re heavy. They’re dense. They’re great at absorbing, storing and releasing heat via the property known as thermal mass. Concrete has a high thermal mass which means concrete walls suck in heat during the day and then slowly release the stored heat during the night through ventilation systems. Aside from the thermal mass of concrete itself, walls are often insulated with materials such as polystyrene to maximize the R-value. They act as a thick insulated barrier against summer sun and winter cold. This characteristic allows for a smaller investment in HVAC equipment on the front end and eases the load on HVAC systems over the long haul, resulting in lower operating costs.

With the implementation of the U.S.Energy Conservation and Production Act, each state is required to maintain a commercial building code to meet minimum energy standards. In addition, by the year 2030, via U.S. Federal Government Executive Order 13514, all government construction and renovation will be required to achieve net-zero energy meaning the energy used by the building must roughly equal the renewable energy created. These types of mandates make PCI-certified building products an attractive choice for owners and designers who understand and appreciate the value of a well-constructed, energy efficient structure.

There are countless attributes that make precast concrete building systems a winner. From beauty to durability to energy efficiency...precast concrete not only looks great, it performs exceptionally well over the life cycle of the structure.

References

www.pca.com | www.pci.org | www.nitterhouseconcrete.com | www.concretecentre.com

PCI Certified Precast Plants... A Recipe for Success

The recipe for a PCI certified precast concrete manufacturing plant involves a complex list of ingredients. Being granted the “PCI certified” seal of approval is not something that occurs by simply paying a fee or joining an association.

The recipe for a PCI certified precast concrete manufacturing plant involves a complex list of ingredients. Being granted the “PCI certified” seal of approval is not something that occurs by simply paying a fee or joining an association. Precast concrete manufacturers who earn this top level designation have invested serious time and money to ensure the products that roll out of their plants are the best of the best. High level decision makers in the building industry understand the value of designating only PCI certified products and specifically call for them in the job requirements.

So what exactly goes into this giant mixing bowl of success?

OVERSIGHT

Oversight of everything… from the physical manufacturing plant, to the personnel who run them, to the crew in the field who carefully erects each piece with precision and skill...the whole process has been evaluated and tweaked to the top level of industry standards that have been developed and tested through decades of study and use. Each plant creates and maintains an approved Quality Service Manual (QSM) that serves as a “living” reference for plant personnel and project owners alike.

EXPERTISE

No one can guide the design process better than the highly qualified personnel in a precast plant. From shapes and sizes to colors and textures, PCI certified plants are filled with industry professionals who know and understand what is possible and how to best meet owner expectation. From value engineered options to state of the art connection systems, if it has to do with precast, rest assured PCI certified personnel are knowledgeable and eager to answer questions and share suggestions.

SURPRISE

Unannounced and random inspections, in the form of bi-annual audits, of precast manufacturing plants are conducted to ensure the products being produced and the processes in use meet project specifications. Every piece...every time is manufactured just as it was designed in a PCI certified plant.

STANDARDS

Only the highest standards are implemented in PCI certified plants.This philosophy lends itself to consistent, efficient processes that produce top level products with minimal error in a time saving and cost saving manner. Project specifiers demand PCI certified products on their jobs because they understand that the real value in any project comes from a structure that is sustainable, maintainable and durable. You get what you pay for! Eliminating/minimizing future repairs and maintenance issues all play into the why it makes sense to choose a PCI certified precast producer from the start.

The end product is only as good as the pieces that are used to create it. PCI has, and always will, strive to be the best of the best. Each and every PCI producer has earned, and continues to earn, their valuable designation through hard work, diligence and a desire to ensure the PCI name will always stand on the top rung of the ladder in the precast concrete industry. This is #HowPrecastBuilds.

Here a just a few of PCI Gulf South’s PCI certified plants.

ALFRED MILLER

FORTERRA

FIBREBOND

TINDALL

Interested in becoming a PCI certified plant? Take a look at the resources below on how to get started.

Organizing Your Precast Plant

One of the most productive ways to keep a precast plant organized is through the implementation of Lean manufacturing methods. The core concept of Lean manufacturing is to reduce waste from the manufacturing process and improve efficiency by utilizing the input of pant personnel to provide input into possible improvements.

One of the most productive ways to keep a precast plant organized is through the implementation of Lean manufacturing methods. The core concept of Lean manufacturing is to reduce waste from the manufacturing process and improve efficiency by utilizing the input of plant personnel to provide input into possible improvements.

The following methods have been found to be successful for creating and maintaining an organized precast plant. Many of the ideas listed below were generated by employees who worked together to discover areas in need of improvement. The philosophy of employee engagement in the process creates “buy in” where employees recognize the changes aren’t happening TO them, but rather, FOR them.

Rolling Tool Carts

Rolling tool carts allow plant set-ups to be flexible and easily adjusted. Carts save time and energy by allowing bulky items to be moved without physical exertion or multiple employees.

Tool Walls & Shadow Boards

Tool organization assists personnel when storing tools and makes it easy to see if anything is missing or out of place when shutting down for the day. Subsequently, each new day starts with everything organized and ready to go.

Established locations for specific items

Establishing specific locations for specific items results in everyone knowing where to find what they need. Established locations saves time “hunting” for “lost” items.

Labeled Fork Racks for embedded plates

Following the same concept of shadow boards and labeled bins, having a designated and labeled location for embed plates keeps items collected and centrally located for ease of use.

Tool Boards for each precast bed

Tool boards for each precast bed reduces the need for personnel to locate and carry needed tools from one bed to the other. Less steps = less fatigue + less time wasted.

Cross-Training Personnel

Cross training plant personnel involves multiple employees mastering the same job tasks. By employing this technique production time is not lost or slowed when an employee is not at work. This practice is also key when an employee leaves the company and a new employee has not been secured or trained.

Designated Recycling Area

Insulation, strand and wash water are all examples of recyclable materials that can be reused or repurposed in an effort to help reduce waste and create a cleaner work environment. Repurposing and recycling are not only environmentally friendly but they reduce costs and waste.

Recording process for broken tools and equipment

Creating a designated log and location for broken tools reduces frustration and potential safety issues by pulling items in need of attention to the side for assigned personnel to determine if repair or replacement is needed.

Assigned Tasks for personnel

Assigning a specific employee with an organizational tasks to be completed daily is a great way to keep the plant organized, add responsibility and hence “buy in” from plant personnel. Employees are more likely to return items and follow organizational processes throughout the day if they know they will be responsible for “putting the pieces back together” at the end of the day.

Reward

It doesn’t matter how old you get or where you work, being appreciated and rewarded for your effort feels good. Rewards can be big or small and can be planned or spontaneous. From a pizza lunch on a Friday to a big box of warm donuts on a cold Monday morning, employees recognize and value being treated well when they are working hard to follow plant processes.

Labeled Bins

Bins that are properly labeled make it easy for both new and experienced personnel to locate needed items. Labeled bins also streamline the inventory process.

It’s important to remember is that there is room for improvement in every work environment. Nobody knows the lay of the land inside a precast plant better than the employees on the floor who spend countless hours creating product. Through a process where employees observe each other and work shoulder to shoulder to streamline processes, the use of the Lean Manufacturing model is a no brainer for improving productivity, safety and the all important bottom line.

![2012 GATE Logo #186[3449].jpg](https://images.squarespace-cdn.com/content/v1/5b70ddec55b02c6b27335114/1574440265229-XD9QRGROB5M7FMVSXQZY/2012+GATE+Logo+%23186%5B3449%5D.jpg)